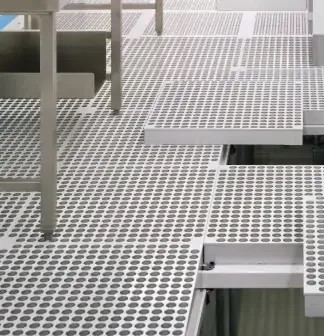

Modular Partition

Modular cleanroom walls are a composite construction of two skins of high pressure Stainless and Pre-coated Galvanized Iron framework with a sealed and insulated interior. The assembly is self-supporting. Additional wall heights can be achieved by using a stacking technique. The Modular Clean room walls panel seams are sealed by silicone with a perfectly flush finishing. Insulation materials are sandwiched between the two skin layers and sealed from the exterior by the SS framework. There is a selection list of materials for insulation and wall skins according different needs in modular cleanroom construction.

General Overview

- Our cleanroom solutions are fully compatible with a wide range of chemicals commonly used for cleaning and sanitizing, ensuring optimal efficiency and safety in your cleanroom environment.

- We have successfully installed cleanroom areas across all major pharmaceutical companies, demonstrating our expertise and reliability in maintaining the highest standards of cleanliness and compliance in regulated industries.

- The installation process is designed to be straightforward and efficient, allowing for a true modular cleanroom design that can adapt to your specific operational needs. This flexibility promotes quick setup and scalability.

- Our state-of-the-art modular cleanroom technology incorporates the latest advancements, providing you with a robust infrastructure that meets stringent industry standards for air quality and contamination control.

- With flush surfaces throughout the cleanroom, we minimize dust accumulation and facilitate superior cleaning protocols, enhancing the overall hygiene of the facility.

- We utilize high-quality, scratch-resistant materials that ensure long-lasting performance and maintain the aesthetic integrity of the cleanroom, thereby reducing maintenance costs over time.

- The design allows for easy modification during partition wall installation, giving you the freedom to reconfigure your space to accommodate changing requirements or workflows with minimal disruption.

The Chempharm unique standard wall skin is an anti-scratch high-pressure laminate (impregnated with a special phenolic resin to be fire resistant). The high-pressure laminate can be easily milled to allow flush mounting of all covings and accessories and guarantees compliance with GMP rules for cleanroom cleaning. The Modular cleanroom wall system is flexible thus allowing easy installation and accepts changes to design in the field and can be reconfigured for use in other locations.

Why Choose Chempharm India for Clean Room Panels?

- Expertise:

With decades of experience as a Prefabricated Clean Room Manufacturer, we deliver tailored solutions. - Compliance:

We adhere to all relevant international standards for cleanroom construction. - Innovation:

Our advanced designs integrate modern technology with sustainable practices. - Customer Focus:

We provide dedicated support from design to installation, ensuring client satisfaction.