Request a Quote

Ready to Work Together? Build a project with us!

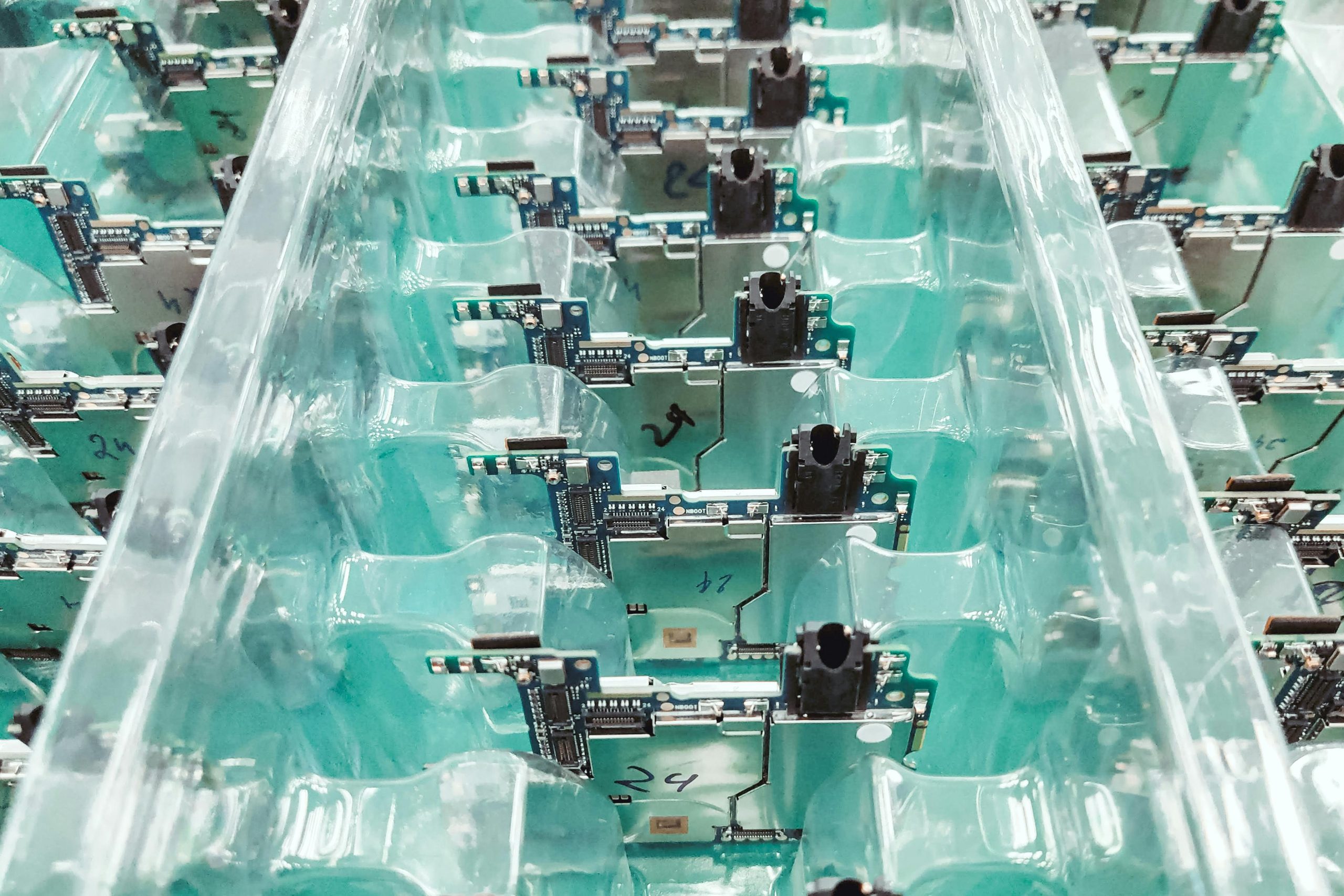

At Chempharm India, we specialize in designing and constructing clean rooms customized for the electronics industry. Our clean room solutions are engineered to create a controlled environment that minimizes the risk of contamination, ensuring the integrity and reliability of sensitive electronic components.

Our expertise spans from concept to completion in the Industry. We excel in providing turnkey solutions for setting up manufacturing plants. Our competitive edge lies in our advanced manufacturing setup, which is one of the largest in capacity, equipped with state-of-the-art German and Japanese fabrication machines. Chempharm implemented first facility in India to set up SEMICON clean room project in India with aluminum honey comb panels for DRDO (Defense research organizations) and also India’s First Semicon Pilot Facility Set Up for Stericon. With 40 years of experience, we were pioneers in this field in India.

Key Features of Our Clean Rooms In Electronics and Semi-conductor Manufacturing Clean Rooms:

- Strict Contamination Control: In the electronics manufacturing process, even the smallest particle can cause significant damage. Our clean rooms are designed with advanced filtration systems, including HEPA and ULPA filters, that effectively capture airborne particles as small as 0.3 microns. This meticulous control of airborne contaminants is essential for protecting delicate electronic components.

- Customized Environments: We recognize that different electronics applications require different environmental conditions. Our clean rooms can be tailored to meet specific temperature, humidity, and pressure requirements, ensuring optimal conditions for operations efficiency.

- Modular Design: Our clean rooms are constructed with a modular approach, allowing for easy reconfiguration as your production needs change. This flexibility helps keep up to evolving technologies and market demands without the need for extensive renovations.

- Enhanced Workflow Efficiency: Our clean room designs focus on optimizing workflow. By integrating efficient layouts and access points, we ensure that materials and personnel can move seamlessly within the space, reducing the risk of contamination and improving overall productivity.

- Compliance with Industry Standards: All of our electronics clean rooms are designed to meet industry standards and certifications. This compliance ensures that your facility adheres to the best practices in contamination control and product safety.

- Comprehensive Validation and Monitoring: We implement rigorous validation protocols to ensure that your cleanroom operates effectively. Our environmental monitoring systems continuously track critical parameters, providing real-time data to help maintain optimal conditions and facilitate compliance with quality standards.

Technical requirements and relevant standards

- Class 1000 Cleanroom Compliance: Cleanrooms for electronics and semiconductor manufacturing often meet ISO Class 6 (Class 1000) standards, essential for Electronics Manufacturing Services and ODM (Original Design Manufacturer) applications in electronic design.

- Compliance Requirements and Standards: Compliance with USFDA, EUGMP, and WHO guidelines ensures global standardization in cleanroom operations. Cleanroom entrances use gowning rooms or antechambers to prevent contamination, while custom passthroughs maintain strict environmental control.

- Design, Commissioning & Validation: Cleanroom design focuses on validation, commissioning, and modular setups suited for advanced technology centers and modern manufacturing facilities.

- Leadership in Cleanroom Development: Emphasizing top-tier cleanroom technology, these facilities integrate cutting-edge equipment, materials, and protocols.

Why Choose Chempharm India?

With extensive experience in cleanroom solutions for the electronics sector, Chempharm India is your trusted partner in creating a reliable and efficient manufacturing environment. Our commitment to quality and customer satisfaction ensures that your cleanroom will support the production of high-performance electronic devices.

For more information about our electronics clean room solutions or to discuss your specific requirements, please contact us today!

Experience, expertise and assistance are the key components of our products and services. Our client portfolio is too extensive for us to name all the companies that we have supplied over the years. However, we hope this brief summary will serve to portray the diversity and scale of our clean room design, manufacture and supply program around the world, including stainless steel fabrication and HVAC/AHU.